Efficient and Cost-Effective Filtration by Zedex Industries

At Zedex Industries, we specialize in manufacturing high-performance Melt-Blown Filter Cartridges that deliver superior filtration efficiency and reliability for a wide range of industrial applications. Our filters are designed to meet the strictest standards, providing exceptional particle retention and longer service life, ensuring optimal performance in industries like water treatment, pharmaceuticals, food and beverage processing, and many more.

What We Do

NORMAL SURFACE

ORANGE SURFACE

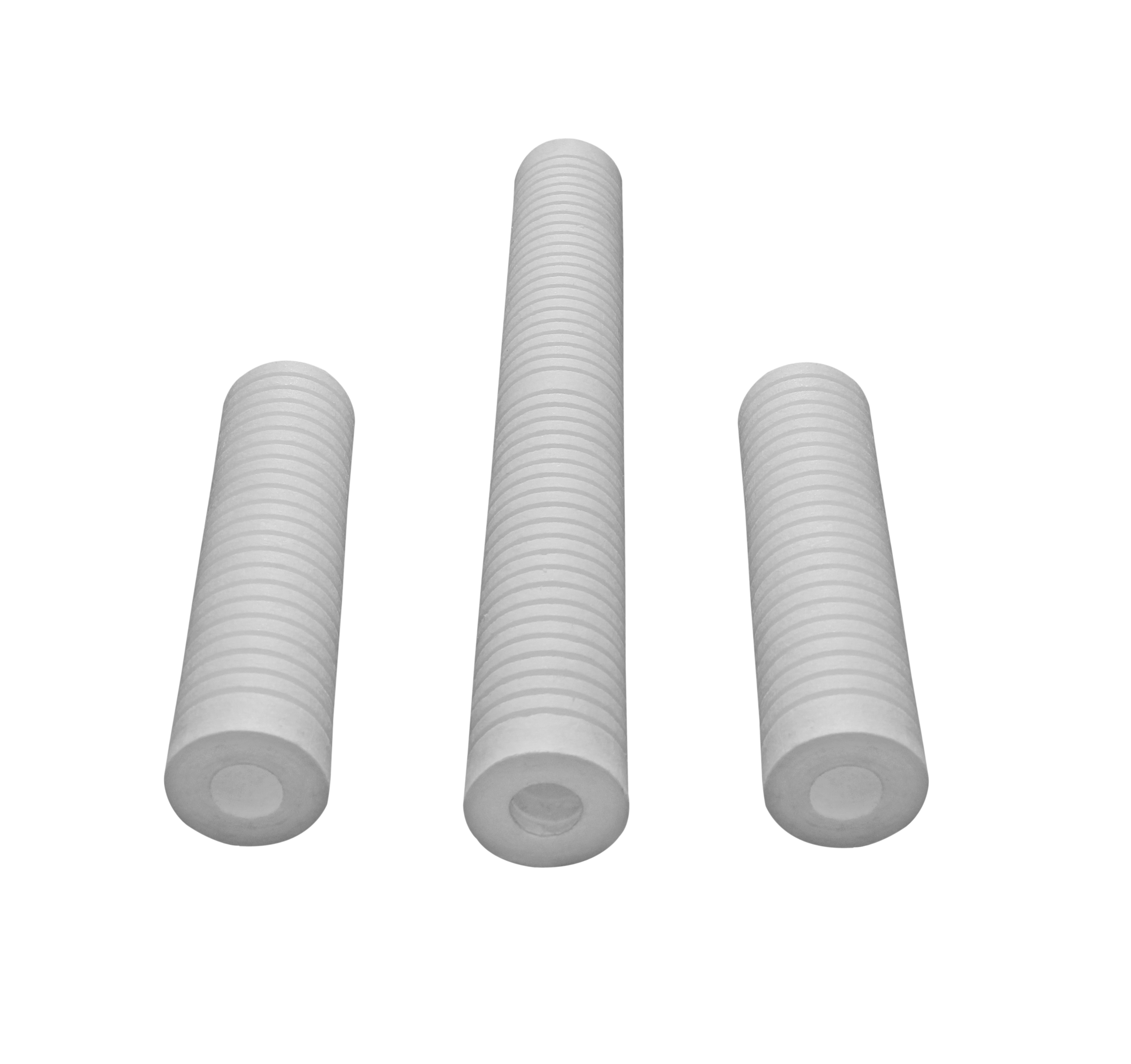

GROOVE SURFACE

DOTTED SURFACE

LINER SURFACE

Why Choose Zedex Industries Melt-Blown Filter Cartridges?

PP melt-blown filter cartridges are among the most widely used filtration elements in domestic and industrial water treatment projects. Renowned for their efficiency and versatility, they play a critical role in ensuring clean and safe water. In this article, we’ll provide a comprehensive introduction to PP melt-blown filters, covering their structure, features, applications, and benefits. Whether you’re new to filtration or looking to deepen your knowledge, this guide will take you through every essential aspect. Let’s get started!

State-of-the-Art Manufacturing

At Zedex Industries, we use advanced melt-blown technology to produce filter cartridges that offer unparalleled filtration efficiency. Our high-quality materials, including polypropylene and other synthetic fibers , ensure excellent particle capture, durability, and consistent performance.

Graded Density Construction

Our melt-blown filter cartridges feature a graded density construction that ensures the most efficient capture of particles. With coarser outer layers and finer inner layers, these filters efficiently capture a wide range of particulate matter while maintaining a low pressure drop over time.

Customizable for Your Needs

Zedex Industries offers a variety of customization options to meet your specific filtration needs. Whether you need a particular micron rating, size, or material, our team works closely with you to provide a tailored solution.

Chemical Resistance & Versatility

Our melt-blown filters are resistant to a wide range of chemicals, acids, and solvents, making them perfect for diverse industrial applications. Whether you’re dealing with water, oils, solvents, or chemicals, our filters offer reliable and cost-effective performance.

FDA-Compliant Options

For applications in the food and beverage, pharmaceuticals, and other regulated industries, Zedex Industries provides melt-blown filters that comply with FDA and other industry-specific regulations, ensuring the highest standards of safety and quality.

Key Benefits of Zedex Melt-Blown Filter Cartridges

Superior Filtration Efficiency:

Our melt-blown cartridges are engineered to capture particles as small as 0.5 microns, ensuring exceptional filtration performance and improving the overall quality of your product or process.Cost-Effective & Long-Lasting:

With their high dirt-holding capacity and durable design, Zedex melt-blown filters reduce maintenance costs and downtime, providing you with long-lasting performance and fewer filter changes.Wide Range of Applications:

Whether you’re working with water, chemicals, air, or gases, our filters provide reliable solutions for various industries, including water treatment, food and beverage processing, pharmaceuticals, chemicals, petrochemicals, and more.

Applications of Zedex Melt-Blown Filter Cartridges

Superior Filtration Efficiency:

Our melt-blown cartridges are engineered to capture particles as small as 0.5 microns, ensuring exceptional filtration performance and improving the overall quality of your product or process.Cost-Effective & Long-Lasting:

With their high dirt-holding capacity and durable design, Zedex melt-blown filters reduce maintenance costs and downtime, providing you with long-lasting performance and fewer filter changes.Wide Range of Applications:

Whether you’re working with water, chemicals, air, or gases, our filters provide reliable solutions for various industries, including water treatment, food and beverage processing, pharmaceuticals, chemicals, petrochemicals, and more.

Technical Specifications

- Material Options: Polypropylene (standard), Nylon, PVDF, PBT (custom materials available)

- Micron Ratings: 0.5µm, 1µm, 5µm, 10µm, 25µm, 50µm, 100µm (custom ratings available)

- Length Options: 10″, 20″, 30″, 40″, custom lengths available

- Outer Diameter: 2.5″ (standard), 4.5″ (optional)

- Core Options: Polypropylene, Stainless Steel, or custom cores

- Maximum Operating Temperature: Up to 180°F (82°C)

- Maximum Operating Pressure: Up to 60 psi (depending on size and application)

- Flow Rate: Customizable to meet your specific requirements, optimized for low pressure drop and high efficiency.